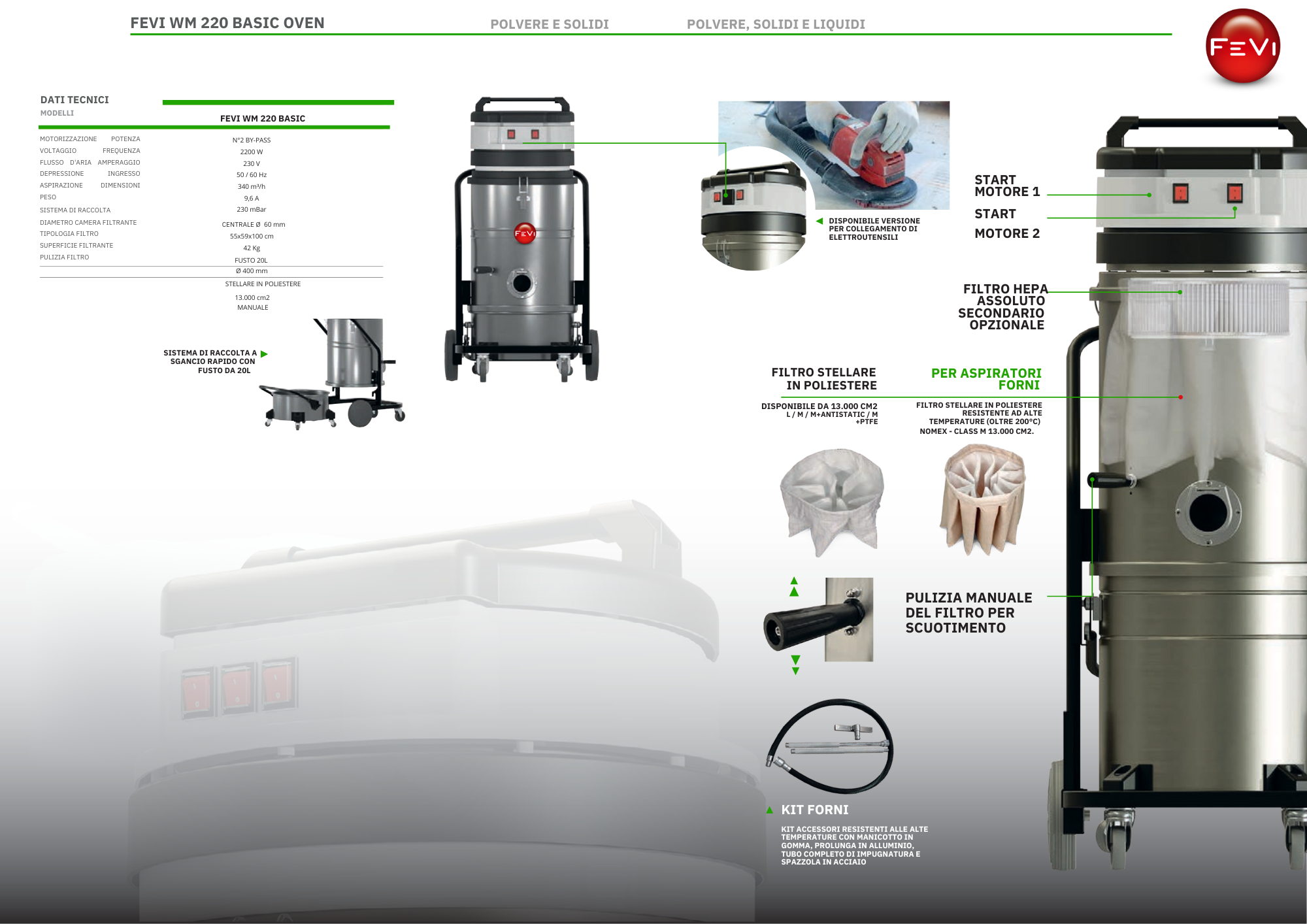

Industrial Vacuum Cleaners for Oven Cleaning

Preventing Contamination in Food Industries

In the food industry, preventing food contamination is essential to comply with good manufacturing practices (GMP) and HACCP protocols. Proper cleaning of equipment, including industrial ovens, is crucial to avoid microbial and cross-contamination, thereby reducing the risk of economic sanctions and preserving product quality.

The Importance of Oven Cleaning

Bakeries and pastry shops often deal with encrusted residues that can become contaminants. Industrial ovens, in particular, require efficient cleaning to ensure food safety and quality. However, cleaning these ovens can be challenging due to high temperatures and the difficulty of reaching all areas.

Efficient Cleaning Solutions

The FEVI WM 220 BASIC OVEN industrial vacuum cleaner is designed to meet these specific needs. With a polyester star filter resistant to temperatures above 200°C and a manual shaking cleaning system, this vacuum cleaner provides an effective solution for oven cleaning. The accessory kit includes a rubber sleeve, aluminum extension, tube with handle, and a steel brush, all resistant to high temperatures, ensuring thorough and safe cleaning.

Benefits of Industrial Vacuum Cleaning

Using the FEVI WM 220 BASIC OVEN not only improves cleaning efficiency but also ensures greater safety for operators by reducing the risk of contact with incandescent materials. Additionally, the quick-release collection system with a 50L drum facilitates residue disposal, improving waste management and optimizing cleaning times.

Conclusion

Keeping industrial ovens clean is crucial to avoid food contamination and ensure the highest product quality. The FEVI WM 220 BASIC OVEN industrial vacuum cleaner offers a reliable and efficient solution for food companies, thanks to its high-temperature resistance and ability to deeply clean even the hardest-to-reach areas.