Fine dust vacuums are essential tools for maintaining clean and safe work environments. Used in various sectors such as construction, chemistry, and mechanics, these devices offer numerous benefits in terms of cleanliness, safety, and productivity. Industrial fine dust vacuums not only improve the working environment but are also crucial for protecting workers' health by reducing exposure to harmful particles.

This article will explore in detail the features, benefits, and applications of fine dust vacuums, with a special focus on FEVI models, including FEVI 220 ICLEAN, FEVI 350 ICLEAN, and FEVI 221 PULSE.

Why Use a Fine Dust Vacuum Cleaner?

Greater Cleanliness

Maintaining a clean work environment is fundamental to operational efficiency. Fine dust vacuums effectively remove dust particles, ensuring that machinery and equipment can operate at their best. This reduces downtime and improves the quality of the final product.

Greater Safety

An environment free of fine dust significantly reduces the risk of workplace accidents, such as fires and respiratory problems among workers. Fine dust, when inhaled, can cause severe lung damage, making the use of vacuums with high-efficiency filters crucial.

Greater Productivity

A clean and well-maintained environment translates into fewer interruptions and unforeseen events, thus increasing overall productivity. Fine dust vacuums help keep work areas operational and safe, improving the efficiency of the production process.

Features of Fine Dust Vacuums

Suction Unit

Power and airflow are crucial elements to ensure adequate performance. Vacuums must be chosen based on the specific needs of the activity, considering the amount and type of dust to be removed

Filtration

An efficient filtration system is essential to ensure that fine dust is effectively removed from the air. HEPA filters are highly recommended to capture the smallest particles and prevent them from being reintroduced into the environment.

Filter Cleaning System

The filter cleaning system helps maintain the vacuum's performance by reducing the downtime needed for maintenance. This allows continuous and efficient operation.

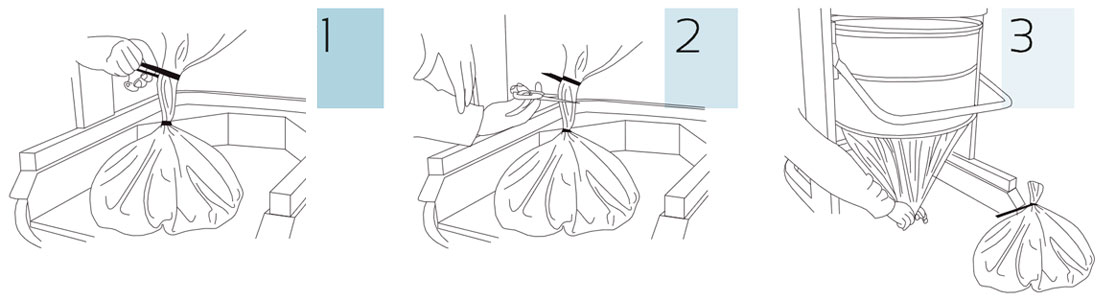

Material Collection System

The method of material collection can vary, simplifying the disposal or recovery of the vacuumed material. Materials can be collected in containers or bagged directly for safe disposal, and the FEVI 221 PULSE model is ideal for this type of collection.

Applications of Industrial Fine Dust Vacuums

Fine dust vacuums are used in a wide range of sectors, including:

- Construction and Site: Industrial vacuums for the removal of dust generated by drilling, milling, and cutting activities.

- Chemical and Pharmaceutical Industry: Industrial vacuums for handling toxic and harmful dust.

- Wood and Metal Processing: Industrial vacuums for removing chips and dust from production processes.

- Additive Manufacturing and 3D Printing: Industrial vacuums for keeping production areas of advanced components clean.

- Biomass Plants and Foundries: Industrial vacuums for handling dust in complex industrial environments.

FEVI Models: FEVI 220 ICLEAN, FEVI 350 ICLEAN, FEVI 221 PULSE

FEVI 220 ICLEAN

The FEVI 220 ICLEAN industrial vacuum is a high-power single-phase vacuum, ideal for vacuuming fine dust in large industrial areas. Equipped with an automatic filter cleaning system, it guarantees continuous operations without maintenance interruptions.

FEVI 350 ICLEAN

FEVI 350 ICLEAN offers greater suction capacity and high efficiency thanks to its HEPA filters. It is particularly suitable for environments where air quality is a priority, such as in chemical and pharmaceutical industries.

FEVI 221 PULSE

The FEVI 221 PULSE industrial vacuum is designed for intensive operations in challenging environments, allowing the safe vacuuming of fine dust and collecting it in a continuous 20-meter long bag. With its continuous bagging system, it is perfect for removing toxic and hazardous dust, always ensuring a safe working environment.

Tips for Using Fine Dust Vacuums

- Regular Maintenance: Perform regular maintenance of vacuums to ensure optimal performance and long device life.

- Staff Training: Ensure that staff are adequately trained in the use and maintenance of vacuums to maximize efficiency and safety.

- Air Quality Monitoring: Implement air quality monitoring systems to promptly identify any problems and intervene promptly.

Fine dust vacuums are indispensable tools for any industrial environment. Choosing the right model, such as the FEVI 220 ICLEAN, FEVI 350 ICLEAN, and FEVI 221 PULSE, can make a difference in terms of safety, cleanliness, and productivity. Investing in these devices not only protects workers' health but also improves overall operational efficiency.